Time : December 12, 2023

Abstract: The application status quo of admixture ceramics bearings in high rate working condition is introduced. The mechanical nature of Si3N4 ceramics material and bearing steel material are compared over – all , various predominance of admixture ceramics bearings in high rate working condition are analyzed. It also home illuminates that compared with the same model number ordinary steel bearings. The usage performance of the late – model admixture ceramics bearings is better , and the usage life is longer.

Key words: admixture ceramics bearing; high rate working condition; Si3N4; analysis

With the rapid development of industrial technology, the requirements for mechanical equipment are also increasing, and working conditions such as high speed, high precision, high load, and high temperature are also increasing. The development of high-speed machining technology has promoted the process of high-speed machining of machine tool spindles. At present, the spindle of the machine tool ranges from 3,000 to 5,000 r/min developed to 15,000 to 70,000 r/min. For example, the vertical machining center of Boston Digtal in the United States has a spindle speed of 60,000 r/min, a high-speed CNC boring and milling machine from Mikron, Switzerland, with a spindle speed of 42,000 r/min, China has already introduced spindle speeds ranging from 15,000 to 25,000/min in the past few years. This will inevitably put forward new requirements and higher technical indicators for the supporting shaft and shaft components – bearings. The original steel bearings are difficult to adapt to such high speeds, and the use of hybrid ceramic bearings (using Si3N4 ceramic material for rolling elements and bearing steel for inner and outer rings) can fully leverage their performance advantages.

Hybrid ceramic ball bearings were initially mainly used in aerospace equipment, such as the United States using them on hydraulic pumps in space shuttles as early as the 1960s, and Japan and Germany also using them on aircraft engine equipment accordingly. In the past 10 years, it has been widely used in mechanical equipment such as high-speed electric spindles, machine tool spindles, dental drills, hard disk drives, and high-speed running instruments and meters. Due to the emergence of hybrid ceramic ball bearings, high-speed (dm=1.5 million) cutting that cannot be achieved with previous forms of all steel bearings and lubrication methods has become possible, and the spindle has reached practicality. In addition, the speed range that grease lubrication cannot reach (dm=1 million) is also due to the emergence of this type of bearing, which makes the low-temperature rise of the spindle practical. At present, hybrid ceramic ball bearings are used in computer fan heat sinks, with an effective service life of 80,000-100,000 hours; 2-3 dB lower under the same specifications and speed; Up to 8,000 r/min The rotation speed of the min bearing will not generate heat. It effectively solves the problem of high noise and shortened service life caused by CPU fans pursuing speed and heat dissipation performance.

The maximum working speed of the drum on some high-speed winding head equipment for chemical fibers is 10,800 r/min, working temperature around 100 ℃, working load is variable load. The original use was all steel special bearings imported from Japan, and the service life of the bearings was only 0.5 years. Through improvement, not only was the temperature rise of the bearings effectively controlled, but the service life of this hybrid ceramic ball bearing can reach about 2 years, which is 3-5 times the original service life.

The AC generator currently used in some modern cars operates at a speed of 20,000 r/min, ambient temperature reaches 200 ℃. To meet the performance requirements, fluororubber sealing rings, high-temperature resistant and fatigue resistant new lubricating grease, and mixed ceramic ball bearings will be used to improve their reliability and increase their lifespan by more than 5 times. There is a trend for hybrid ceramic ball bearings to replace all steel bearings in automotive components that operate under high-speed conditions such as turbochargers.

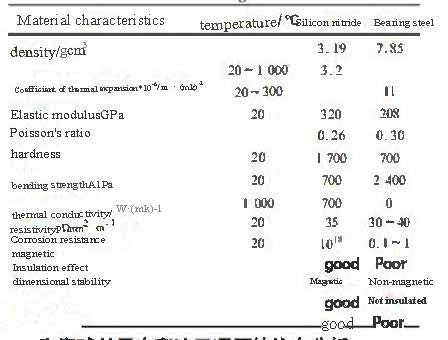

The Si3N4 ceramic material used on bearing rolling elements has many physical properties compared to bearing steel, such as light weight, low coefficient of thermal expansion, high hardness, high temperature resistance, corrosion resistance, and non-magnetic properties. The characteristics of bearing steel and ceramic silicon nitride materials are shown in Table 1.

Tab. 1 Performance and difference of Si3N4 ceramics material and bearing steel

(1) From the analysis of centrifugal force on high-speed bearing rolling elements, under high-speed rotation conditions, the force on the bearing mainly comes from external loading and centrifugal force generated by high-speed. The centrifugal force on the bearing rolling elements

In the formula ρ—— Density of rolling element, kg/m3;

Db – diameter of rolling element, m;

dm – pitch diameter of rolling element bearings, m;

ωm – Rolling element common angular velocity, rad/s.

From equation (1), it can be seen that the centrifugal force of the rolling element is directly proportional to the square of the velocity. Therefore, as the velocity increases, the centrifugal force of the rolling element rapidly increases, even far exceeding the external load. According to Table 1, the density of ceramic rolling elements is 40% of that of steel rolling elements, and the centrifugal force generated by ceramic rolling elements is much smaller than that generated by steel bearings. After the speed increases, the contact stress is directly proportional to the centrifugal force of the rolling element, while the contact stress is inversely proportional to the rolling service life of the bearing in cubic terms. On the other hand, under high-speed conditions, the centrifugal force of the rolling element is directly proportional to the equivalent dynamic load P, based on the service life of the steel bearing

![]()

In the formula, C – rated dynamic load of the bearing;

α 1, α 2, α 3- Life correction coefficient;

P – bearing equivalent load;

ε—— Exponential, generally taken as ε= 3 or ε= 10/3.

It is obvious from the analysis of force conditions that the service life of hybrid ceramic ball bearings is much longer than that of steel bearings under high-speed working conditions.

(2) Analysis of Gyroscopic Moment from High Speed Bearing Rolling Element

The motion caused by gyroscopic torque causes the rolling element to slide along the raceway of the ring, and also causes severe friction between the rolling element and the inner and outer raceways, resulting in a large amount of heat generated by the bearing. The increase in bearing temperature will directly affect the fatigue life of the bearing. The gyroscopic moment acting on the rolling element

![]()

In the formula,

J – the moment of inertia of the rolling element, kg · m2;

ωb – Rotation speed of rolling element, rad/s;

Β – The angle between the rotation axis of the rolling element and the coordinate plane, rad.

It can be inferred from equation (3) that the gyroscopic moment of ceramic ball bearings is smaller than that of steel ball bearings. The JW series high-speed winding head mentioned above uses BN35 hybrid ceramic ball bearings, with a bearing speed of 10,800 r/min Under the condition of min, the experimental temperature rise can be controlled below 55 ℃ and is very stable.

Due to the unique mechanical properties of Si3N4 ceramic material compared to ordinary bearing steel, hybrid ceramic bearings have lower equivalent load, contact stress, temperature rise, and more stable bearing channel clearance compared to steel bearings of the same model under high-speed conditions. Thoroughly improving the various performance of bearings in high-speed environments, facilitating lubrication of bearings, increasing the service life of bearings, and making further increasing the maximum speed of bearings a reality.

2023 December 1st Week XZBRG Product Recommendation:

Full Ceramic Cylindrical Roller Bearings:

Ceramic cylinder roller bearings are made with a single row, two rows, or multi-rows of rolling elements.

the cylindrical roller bearings have line contact between the rollers and raceway, therefore radial load capability is high, making this bearing superior in regards to its ability to withstand heavy loads and impact loads.

They contain cylindrically-shaped roller, which are nevertheless not true cylinders.

Instead, they are crowned or end-relieved to reduce stress concentrations.

This particular geometry results in low friction and allows high-speed applications.