Time : agosto 3, 2023

Abstract: Premature bearing failures of wind turbine generators are occurring frequently. The reasons are mani2 fold, but based on application studies and bearing investigations two main root causes have been identified: electrical current passage, electrical erosion respectively, due to frequency converter supply of doubly – fed induction generators and lubrication and wear related problem s. Strives to give an overview on typical root causes for premature bearing failures in wind turbine generator applications and introduces extra – large (XL) hybrid deep groove ball bearings as a new solution to significantly reduce generator bearing failures and to increase the overall reliability and operating availability of wind turbines.

Key words: w ind turbine genera tors; bearings; solution

The application of power electronics technology in variable speed control is increasing, replacing many traditional speed control methods, such as mechanical gearbox drive, hydraulic drive, etc. The application of frequency converters enables the motor to freely adjust speed from zero to rated speed and keep it running at the appropriate operating point, thereby improving the efficiency and dynamic response ability of the motor while reducing energy consumption. The same technology is also applied to wind turbines. In the past 5 to 6 years, the “doubly fed generator” in large-scale wind turbine equipment has become a typical application and is becoming increasingly popular, allowing wind turbines to operate over a relatively wide speed range. The rotor winding in a doubly fed generator is powered by a frequency converter, and the motor can optimize the generation energy and maintain a stable line frequency while adjusting the active and reactive power while changing the rotor speed. However, due to the introduction of frequency converter systems, bearing failures caused by overcurrent frequently occur and become the main cause of early generator failures. At the same time, it was confirmed that another major cause of bearing failure was lubrication and corresponding wear.

This article elaborates on the fundamental reasons for early bearing failure in wind turbine applications, and introduces the technology of ultra large hybrid ceramic ball bearings. This proposed technology can significantly reduce bearing failure in generators and increase the overall reliability and operational stability of the equipment.

Among various mechanical equipment components, bearings are the most important part. The failure of bearings in motors can also be caused by many other reasons, such as exceeding expected loads, improper lubrication, improper handling during transportation and shutdown, electrical corrosion, damage caused by installation and disassembly, internal pollution of bearings, seal failure, and improper tolerance fit between shafts and bearing chambers. Each factor can cause different damages, and at the same time, they leave their own unique marks in the bearings. Through research on application examples and bearings, it has been found that bearing failures in wind turbines are directly or indirectly related to overcurrent, lubrication, and wear.

1.1 Electrical corrosion

In doubly fed generators powered by frequency converters, the problem of current flowing through bearings is very common, which is called electrical corrosion. Electrical corrosion of bearings usually occurs when current flows from one raceway to another through rolling elements. The degree of damage caused by electrical corrosion to bearings depends on the discharge energy and duration, but the damage effect is basically similar, including small electrical corrosion pits on the rolling element and raceway, rapid lubrication degradation, washboard patterns in the second stage of failure, and corresponding bearing failure.

The heat generated during discharge will cause the surface of the bearing material to melt and create pits, while the metal chips will transfer and detach from their original positions. The metal on the surface of the electrical erosion pit will be re hardened, becoming more brittle than the previous bearing material. Below the re hardening layer is an annealing layer, which is softer than the surrounding material. The damaged bearing surface appears dark, characterized by many small melting pits. These small pits are distributed on the surface and raceway of the rolling element, and their size is very small. Whether on the inner ring, outer ring, or rolling element, their diameter is usually only 5-8 μ M. Therefore, the shape of these pits can only be seen under a very high magnification microscope.

In addition, current discharge also leads to denaturation of internal lubrication in bearings and rapid degradation. The high temperature causes the additives in the lubricating machine to react with the base oil, causing the base oil to burn and carbonize, and the additives will be quickly used up. Therefore, the lubrication machine will become harder or even blackened (Figure 1), which cannot meet the lubrication requirements. The rapid failure of lubrication machines is also a typical mode of failure caused by overcurrent.

Figure 1 Fragment of Ball Bearing Cage (Over current causing lubrication to blackening)

1.2 Lubrication

An important condition for stable operation of rolling bearings to reach their operating life is sufficient lubrication. The function of lubricants is to form a protective oil film, separating rolling contact surfaces, and preventing direct contact between metals. The lubricant shall also protect the corresponding parts from corrosion. When using lubricating grease as a lubricant (commonly used in wind turbines), its functions need to be expanded, such as protecting bearings from solid particles, dust, and water pollution.

Oil has some important properties, including viscosity, oil film forming ability, and density. The most important influencing factors on oil film thickness are the size, speed, temperature, load, and base oil viscosity of the bearing. To obtain certain special properties of lubricating grease, additives are often needed, such as rust inhibitors, which can prevent metal rusting and oxidation of the grease. Wind turbines are installed around the world, enduring different climatic environments and adapting to different environmental changes. For example, the ambient temperature is related to the location, latitude, and season of wind turbine installation. Similarly, there will be significant differences in humidity between wind farms installed in the North Sea and those near the desert.

The lubricants in wind turbines need to adapt to these changes. Sometimes, it is difficult to accurately predict parameters in specific working environments (such as temperature), resulting in poor lubrication performance due to improper selection of lubricating grease. Insufficient lubrication can lead to metal surface fatigue and wear, thereby reducing the lifespan of bearings. If the lubricating film between the rolling element and the raceway is too thin, the metal surface will not be fully isolated, and direct contact between metals will occur. This situation may be caused by pollution, insufficient lubrication, and other factors.

Regular supplementary lubrication of bearings is crucial for ensuring their good operation and achieving their expected lifespan. Usually, in installed wind turbines, the re lubrication of the generator is carried out manually during routine maintenance. During this process, workers have to climb to the top of the tower for work every 6 months, and sometimes during routine maintenance, the re lubrication of the generator may be forgotten; Sometimes such time intervals are too long compared to the actual working conditions of the generator bearings.

1.3 Wear and tear

Usually, there is little wear inside the bearing. When external particle pollution enters the bearing or lubrication is insufficient, it can lead to wear and tear. During shutdown, the vibration of the bearings may also cause wear.

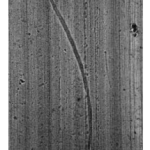

The application of wind turbines often not only needs to adapt to the harsh environment during operation, but also needs to adapt to the shutdown conditions during maintenance. Due to the model, the bearings in the generator are usually open deep groove ball bearings. Even though the bearings are protected by external labyrinth seals, there is still a risk of pollutants entering the bearing chamber. The most common sources of pollution include: pollution caused by insufficient lubrication (such as dry high-quality particles), damaged seals, environmental pollution particles, and pollution caused by improper installation and replacement of bearing chambers. These contaminated particles, after being rolled by the rolling element, will cause fatigue and form spalling on the raceway of the bearing (Figure 2).

During transportation, if the rotor shaft of the generator is poorly fixed and vibration occurs in the clearance of the bearings, these may damage the bearings; Similarly, if the generator is in a shutdown state, vibration over a period of time can also cause bearing damage. For previously designed wind turbines that still do not stop rotating during shutdown, such faults are very common. Therefore, in the updated design, the blades still rotate slowly during shutdown. But when the generator is stationary, there is no lubricant between the components in contact with each other inside the bearings to form an oil film, resulting in direct metal contact between the rolling element and the raceway. If the external vibration is Species reintroduction again, the vibration will cause a very small displacement of the rolling element relative to the raceway. Under such displacement, the small cold welding points and wear between metals will damage the raceway and cause fretting corrosion. This type of damage usually occurs at evenly spaced rollers, exhibiting changes in color or gloss. This type of damage is known as the “pseudo Brinell indentation” (Figure 3).

Figure 2 Traces on the surface of the raceway caused by rolling over contaminated particles

Figure 3 Pseudo Brinell indentation on cylindrical roller bearings caused by shutdown vibration

The hybrid ceramic bearing (Figure 4) consists of a bearing ring made of bearing steel and a rolling element made of bearing grade silicon nitride material. Silicon nitride material is a ceramic material that has many beneficial characteristics: high hardness, electrical insulation, low density, and stability; At the same time, it also has excellent electrical insulation characteristics. Hybrid ceramic bearings have higher speed capabilities and longer service life in most operating conditions compared to ordinary all steel bearings.

Figure 4 Hybrid ceramic bearing composed of bearing rigid material ring and bearing grade silicon nitride (ceramic) material rolling element

A very important characteristic of silicon nitride material is its excellent electrical insulation performance. This performance prevents bearings from being damaged by overcurrent, while also increasing the service life of bearings in variable speed drive motors powered by frequency converters. The density of silicon nitride material is 40% of that of steel material, making the rolling mass of the bearing lighter and having less inertia. This means that the force on the cage is reduced during rapid start and stop, and compared to all steel bearings, the bearing friction is reduced during high-speed operation. Lower friction means lower operating temperatures, longer relubrication intervals, and longer lubricant life. Therefore, hybrid ceramic bearings have superior performance at high speeds. hybrid ceramic bearings are not very sensitive to insufficient lubrication, which makes them have a longer operating life than all steel bearings in more severe dynamic environments or under low operating viscosity lubrication conditions.

Compared with steel, silicon nitride materials have higher hardness and larger elastic modulus, which increases the robustness of bearings and extends the operating life of hybrid ceramic bearings in polluted environments. When operating in poor lubrication and harsh environments, the wear resistance of hybrid ceramic bearings far exceeds that of all steel bearings. On the other hand, balls made of silicon nitride material of the same size have smaller thermal expansion compared to balls made of steel material, which reduces the sensitivity caused by thermal distribution inside the bearing and makes preload control more precise. To ensure optimal quality, uses a complex set of silicon nitride material technical requirements for bearing rolling elements to control quality. This technical requirement includes material strength, macroscopic and microscopic structure of the material, hardness, rigidity, fatigue performance of rolling contact, and the appearance of the finished surface of the rolling element. The various components of hybrid ceramic bearings are selected according to the high requirements of rolling element silicon nitride material. The characteristics of the mixed ceramic materials mentioned above can solve the problems described in the first part of wind turbines. ‘s ultra large hybrid ceramic deep groove ball bearing is a solution that can greatly reduce early bearing failure in wind turbines.

From a technical perspective, hybrid ceramic bearings are the most reliable solution for wind turbine applications. Because it not only has excellent electrical insulation materials that can completely eliminate high-frequency currents flowing through bearings, but also has excellent tribological performance under harsh operating conditions.

has developed a series of ultra large hybrid ceramic deep groove ball bearings (see Table 1), which optimize product performance for wind turbine applications and cover the main model range in mainstream wind farms.

In traditional design, two deep groove ball bearings of the same model are installed in the driving section and non driving end of the wind turbine. In order to avoid overcurrent and solve the problem of electrical corrosion, it is recommended to replace all steel deep groove ball bearings with ultra large hybrid ceramic deep groove ball bearings in the bearings of doubly fed generators. This can solve the wear caused by poor lubrication and pollution, while improving operational reliability.

It is very convenient to replace existing deep groove ball bearings with ultra large hybrid ceramic deep groove ball bearings. This type of bearing follows the requirements of ISO 15:1998 and has the same external dimensions as ordinary bearings. There is no need to redesign the external components of the bearing or install them with special tools, as long as they are disposed of in the same way as ordinary bearings.

4 Conclusion

Due to the special design of doubly fed wind turbines and the introduction of frequency converters, high-frequency stray bearing overcurrent is very prone to occur. Therefore, electrical corrosion and early failure of bearings often occur, which requires the application of electrical insulation to both ends of the bearings. In addition to electrical corrosion, insufficient lubrication and wear have also become an important cause of wind turbine failures. By using insulated hybrid ceramic bearings, current can be prevented from passing through the rolling contact parts of the generator bearings. Due to the use of superior materials and quality control, hybrid ceramic bearings have better technical reliability and more economical long-term cost efficiency in preventing early bearing failure caused by stray currents and poor lubrication. The operational reliability and availability of wind turbines have been improved, and the cost per kilowatt has been reduced. Hybrid ceramic deep groove ball bearings have standard external dimensions and can be replaced with all steel deep groove ball bearings of the same size without the need for special tools or additional work.

More about XZBRG Rodamientos de bolas de contacto angular de cerámica completos:

Cojinetes de bolas de cerámica completos construidos completamente de material cerámico. Las pistas y bolas internas/externas están hechas de nitruro de silicio (Si3N4), óxido de circonio (ZrO2) o carburo de silicio (SiC). Están disponibles como complemento completo (sin jaula) o con una jaula hecha de PEEK o PTFE. Los rodamientos totalmente cerámicos son para aplicaciones de carga media y velocidad media. No es posible lograr la redondez de los anillos interior y exterior que se encuentra con los rodamientos de acero de precisión, por lo que los rodamientos completamente cerámicos tienen clasificaciones de velocidad más bajas.