Time : junio 5, 2023

Abstract: Silicon nitride ceramic bearings have many excellent physical properties such as high strength, high hardness, low density, and high temperature resistance, and are widely used in the aerospace field, especially in aviation engines. With the rapid development of the aviation industry, there are stricter requirements for the performance of silicon nitride ceramic bearings. Silicon nitride ceramic bearings need to operate faster and smoother under high temperature and heavy load conditions. Based on the comparative analysis method, the development status, defects, and future trends of silicon nitride ceramic bearings and steel bearings were compared and analyzed. Previous studies have shown that the high temperature resistance, corrosion resistance and working life of silicon nitride ceramic bearings are far better than those of steel bearings, but their mechanical properties such as fracture toughness and tensile strength still have much room for improvement.

0 Introduction

Silicon nitride ceramics have excellent comprehensive properties such as high strength, high hardness, low density, high temperature resistance, and ultra high speed, and are widely used in the fields of aerospace and equipment manufacturing. Bearings are an important component in mechanical equipment and are widely used. Its main function is to support the mechanical rotating body, reduce its friction coefficient during movement, and ensure its rotational accuracy. Its function is similar to that of human joints, so it is known as a “mechanical joint”. A series of problems such as severe wear and tear, overheating, seizure, and lubricant deterioration of bearings will directly lead to malignant failure of equipment and systems. In aviation engines, the working environment of bearings is very harsh, and being in a high-temperature environment poses a great challenge to the performance of bearings, which can easily lead to bearing failure. The fundamental method to solve this problem is to use materials with better comprehensive performance and further optimize the performance of bearings.

Ceramic bearings have applications in various fields. Zhu Aihua and others compared the performance of steel bearings and silicon nitride ceramic bearings, and found that the main advantage of using silicon nitride ceramic bearings for locomotive traction motor bearings is that they can effectively prevent “electrical corrosion” damage caused by current passing through the bearings; The grease life of ceramic bearings is 3-4 times longer than that of ordinary steel bearings. Zhang Baolin and others studied the new progress of hybrid silicon nitride ceramic bearings. Wen Huaixing et al. studied the research status and development trend of lubrication technology for silicon nitride ceramic bearings. Xun Changtian et al. studied the corrosion behavior of silicon nitride in acid solutions such as H2SO4, HNO3, HCl, HF, and high-temperature SO2 and HCl gases, and summarized its corrosion mechanism. The above results all indicate that silicon nitride ceramic bearings have excellent properties.

1 Silicon nitride ceramic bearing

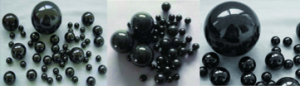

Silicon nitride ceramic bearings have lower density, higher hardness, higher compressive strength, good stability, and significant characteristics such as high temperature resistance, wear resistance, and corrosion resistance. They are widely used in vacuum, high temperature, and high-speed working environments and have a wide range of adaptability. The dynamic and static friction coefficient between silicon nitride ceramics and steel is small, which can effectively reduce the occurrence of burn raceways and cold welding, and even extend the bearing life under harsh conditions. Silicon nitride ceramic bearings are shown in Figure 1.

Figure 1 Silicon Nitride Ceramic Bearing

In recent years, ceramic bearings have been increasingly widely used in various fields. Ceramic bearings can be roughly divided into four applications: high-speed, high-temperature, low-temperature, and general. In terms of high-speed, the sliding speed of hybrid ceramic bearings is much slower than that of all steel bearings, and the heat generated by hybrid ceramic bearings is also much less. Suitable for high-speed aircraft engines such as jet turbines. In terms of high temperature, all steel bearings are difficult to maintain hardness, and liquid lubricants are prone to degradation, while silicon nitride bearings can still maintain good operation. Widely used in aviation and adiabatic engines. In terms of low temperature, steel bearings are prone to adhesion, wear, scratches, and bite, while hybrid ceramic bearings are resistant to wear and scratches. It is mostly used in cryogenic turbopump of rocket engines that provide ultra-low temperature propulsion and use liquid fuel propulsion. Ceramic bearings have corrosion resistance and can be used in various precision and environmentally poor instruments in general applications. Such as vacuum pumps, high-speed electric vehicles, seawater machinery, drilling machines, etc.

2 Performance defects of silicon nitride ceramic bearings

The structure and performance matching of silicon nitride ceramic bearings are the core technologies for design and application, including stress design, thermal design, tribological design, and life design. The stress design should consider the nominal contact stress, additional stress under working conditions, structural and vibration additional stresses, as well as the bearing capacity of the supporting materials. When designing silicon nitride ceramic bearings, the basic structural parameters need to be determined first, and then the matching design of surface tribological performance, working performance design, structural dynamic performance design, thermal characteristic design, lubrication performance compatibility design, and material matching design should be carried out based on the working conditions. This process is cumbersome and complex in procedure and operation.

Figure 2 Silicon nitride ceramic bearings

Compared with bearing steel, its low toughness, high hardness, and moderate bending strength remain the fatal weaknesses of silicon nitride ceramic materials in their sensitivity to damage and defects. High reliability silicon nitride ceramic bearings require complete non-destructive testing to ensure. The differences in material mechanical properties cause significant changes in the stiffness of ceramic bearings, which can lead to significant changes in the support stiffness, dynamic response, and additional dynamic load of the rotor system. This leads to significant changes in dynamic performance design methods, requiring the development of specialized dynamic performance analysis software.

As a new type of material for aviation bearings, aviation ceramic bearings need to undergo a large number of tests to adapt to working conditions. Life verification test is the most basic test, which also requires completing high-speed test, extreme temperature rise test, pollution resistance test, oil cut-off test, and blade detachment impact test. After a large number of experiments, various parameters with clear boundaries can be obtained and provide scientific basis for the design of ceramic bearings.

3 Research progress in high reliability ceramic bearing technology

The development history of aviation bearing technology has been from M50 to M50 NiL, Cronidur 30, and now to the widely used silicon nitride ceramic material. The rapid development of aviation bearing technology cannot be separated from the research and development of bearing materials. In the future, aviation bearings will develop towards environmentally friendly, lightweight, universal, and high-strength technologies, and corresponding protection and testing technologies will also have significant development.

Silicon nitride ceramic balls are an important component of silicon nitride ceramic bearings, and the manufacturing process of silicon nitride ceramic balls can be divided into four stages. The first stage is the preparation of silicon nitride raw materials, which involves evenly mixing silicon nitride powder and sintering additives in a certain proportion. The second stage is the molding of silicon nitride ceramic balls, commonly used methods include extrusion molding, injection molding, dry pressing molding, and injection molding. The third stage is the densification sintering of silicon nitride ceramic balls, with sintering methods including atmospheric pressure sintering, hot pressure sintering, gas pressure sintering, and hot isostatic pressing sintering. The fourth stage is post-processing grinding processing, which includes rough grinding, fine grinding, rough grinding, fine grinding, and polishing. The process flow is shown in Figure 3.

![]()

Figure 3 Production process of silicon nitride ceramic bearings

In the future, when ceramic bearings have better performance and can be manufactured at a low cost, they will be transformed into civilian technology. It can be widely used in civil high-speed machine tools, low-temperature engineering, high-speed motors, chemical industries, and other industries, and can fully cover all application fields of precision, medium speed and above all steel bearings. The performance price ratio is much better than that of all steel bearings, and the lifespan can be increased by more than three times compared to the current bearing lifespan, saving a lot of downtime for maintenance, reducing scrap, and reducing inventory of bearing spare parts. In addition, due to its high technological content, counterfeiting is impossible and investment risks are low.

The failure form of alumina, zirconia, and silicon carbide ceramic balls is debris, while the failure form of silicon nitride ceramic bearing ceramic balls is peeling. The rolling contact fatigue of silicon nitride ceramic balls is an important performance indicator for measuring the performance of silicon nitride ceramic bearings. The number and size of surface pores, uniformity of pore distribution, surface roughness of silicon nitride ceramic balls, residual stress of silicon nitride ceramic balls, and lubrication conditions all have a significant impact on the rolling contact fatigue strength of silicon nitride ceramic balls. Figure 4 shows the surface microstructure of silicon nitride ceramic bearings.

Figure 4 Surface Micromorphology of Silicon Nitride Ceramic Bearings

The corresponding protection detection systems include monitoring technology for the operational health status of ceramic bearings, non-destructive testing, and reliability evaluation technology. The fluctuation of bearing performance and bearing failure can lead to serious problems or even paralysis of the system. Intelligent Health Monitoring Systems is the overall development trend of future aviation equipment technology monitoring, and the health status monitoring of bearings and teeth is the most important one. Non destructive testing technology is a detection technology for surface and subsurface defects and damage, which can effectively control the quality of finished ceramic components, study the general patterns and patterns of damage suffered, obtain the ultimate ability to resist damage, and establish reliability evaluation models.

4 Conclusion

Ceramic bearings have been widely used in the fields of aviation, aerospace, and high-end manufacturing. Silicon nitride ceramic bearings have become the backbone of aviation bearings and are striving towards popularization. For high-performance requirements such as high temperature, high speed, long life, and mass load required by aerospace, ceramic bearing technology needs to be continuously developed, researched, and innovated.

More about XBRG Angular Contact Ball Bearings:

Los rodamientos de bolas de contacto angular soportan cargas radiales y axiales a través de anillos de rodadura asimétricos que alojan los elementos rodantes esféricos del rodamiento, también llamados bolas de rodamiento, en ángulo. Cuanto mayor sea el ángulo entre el rodamiento y su eje, mayor será la carga axial que puede soportar el rodamiento. Debido a que la carga axial es proporcional a la carga radial, una mayor capacidad de carga axial significa una menor capacidad de carga radial.