Time : Декабрь 5, 2023

Abstract: To further study the friction characteristics of ceramic bearing, differences of friction characteristics between the hybrid ceramic bearing and the all-steel bearing were investigated by experiments using the basic friction tester under low-volatility grease lubrication. The results show that the static friction torque, the temperature rise and the friction power loss at high-speed running of hybrid ceramic bearing are less than those of all-steel bearing. The acceleration vibration performance of both bearings is almost the same. The value of velocity vibration of the hybrid ceramic bearing is much smaller than that of the all-steel bearing at low and inter-mediate frequency, while the result is reverse at high frequency. The application of ceramic bearing to the momentum wheel of satellites can imp rove the angular momentum-mass ratio of wheel, reduce the mass of the system and obtain better function density.

Key words: hybrid ceramic bearing; satellite; momentum wheel; low-volatile greases; friction experiments.

The biggest advantage of small satellites is their high functional density, so their flywheel attitude adjustment system requires the highest possible angular momentum/mass ratio and the smallest possible volume There are two ways to improve the flywheel angular momentum/mass ratio: one is to optimize the design of the flywheel structure, and the other is to increase the flywheel speed At present, the flywheel speed is relatively low (usually between 3000 to 6000 r/m in), mainly due to bearing limitations. In recent years, ceramic bearings using SI3N4 ceramic material as bearing components have shown better performance than steel bearings under various harsh operating conditions (heavy load, high speed, corrosion, etc.), with higher ultimate speed and longer service life. Due to the late emergence of ceramic bearings, research on their performance has not been fully conducted, especially in special environments and conditions. This article conducted performance tests on FAG7002 hybrid ceramic ball bearings, and compared them with steel ball bearings of the same model in terms of starting friction torque, vibration (speed, acceleration), temperature rise at high speed, and power consumption.

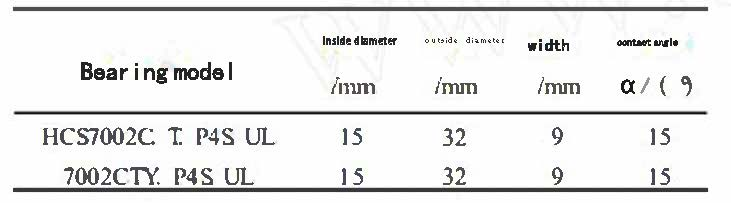

The test bearings are FAG (model HCS7002C. T. P4S. UL) and NSK (model 7002CTY. P4S. UL), each with four sets of bearings. Their external dimensions are shown in Table 1, and both bearings have an accuracy level of P4 (ultra precision level) Both types of bearings adopt grease lubrication method, and the lubricating grease used is FAG low volatility high-speed high-quality lubricating grease L52.

Table 1 External Dimensions of Test Bearings

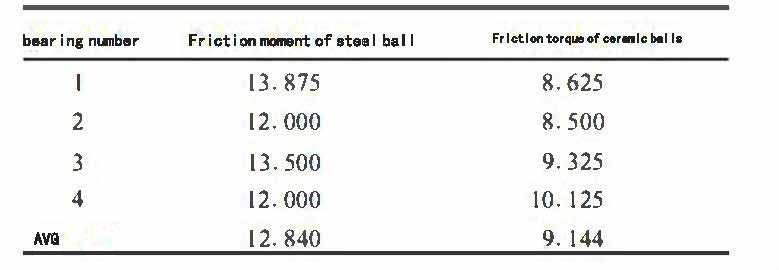

2.1 Static Friction Moment Test

A static friction torque comparison test was conducted on the YZC-II bearing friction torque tester for two types of bearings, and the results are shown in Table 2 The average static friction torque of ceramic ball bearings is smaller than that of steel ball bearings of the same model.

/g· cm Table 2 Static Friction Moment Comparison Test Results

2.2 Speed and acceleration vibration test

Before the test, the bearing is cleaned with light gasoline, and then FAG L52 lubricating grease is added to the inner cavity of the bearing. In order to evenly distribute the lubricating grease in the bearing cavity, a double-sided grease injection method is used In order to achieve good lubrication effect, the amount of grease injected is approximately 30% of the bearing cavity volume [4] When the amount of grease injected is between 25% and 30%, its lubrication life is optimal [5] The use of a specialized grease injector modified from a medical syringe for grease injection can ensure that the amount of grease injected into the test bearing is strictly the same.

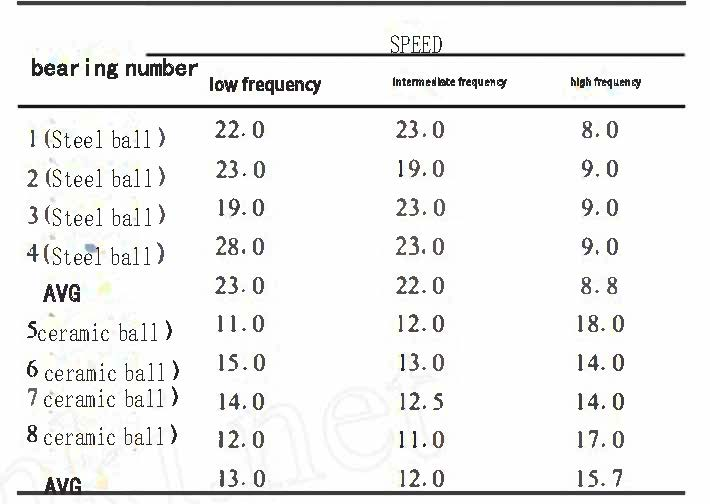

The speed vibration test was conducted on the speed vibration instrument S0910, with a speed of 1800 r/m in and an axial preload of 60 N. The test results are shown in Table 3 The average velocity vibration value of ceramic ball bearings is smaller in the low and medium frequency bands than that of steel ball bearings of the same model, while the former is larger in the high frequency band.

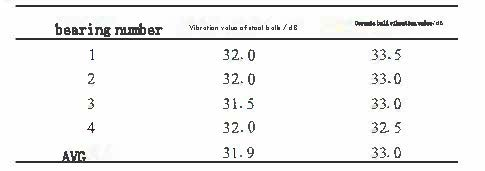

The acceleration vibration test was conducted on the accelerometer B1010 at a speed of 1500 r/m in, with an axial preload of 60 N. The test results are shown in Table 4 The average acceleration vibration value of ceramic ball bearings is comparable to that of steel ball bearings of the same model, with the former slightly higher than the latter.

Table 3 Speed Vibration Comparison Test Results μ M · s – 1

Table 4 Acceleration Vibration Comparison Test Results

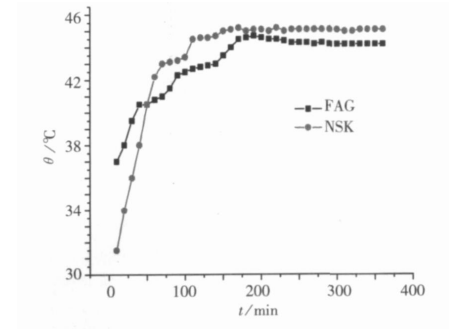

2.3 Temperature rise comparison test

The temperature rise comparison test was conducted on the B8-25 high-speed electric spindle. Two test bearings were installed in pairs on the experimental electric spindle under the following conditions: a rotational speed of 20000 r/min, a radial load of 75 N on the bearings, and an axial load of 45 N. After starting the machine, the temperature of the test bearings was measured every 10 minutes for 6 consecutive hours. The average temperature values of the four tested bearings at the same time were taken, and the results of the temperature rise test are shown in Figure 1.

Figure 1 Comparison Test Results of Bearing Temperature Rise

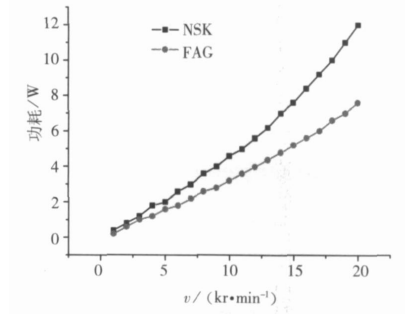

2.4 High speed friction power consumption comparison test

The high-speed friction power consumption test was also conducted on the high-speed electric spindle model B8-25 There are two test bearings (NSK7002CTY. P4S. UL) installed on the experimental electric spindle. The load on the electric spindle is as follows: radial load of 75 N, axial load of 45 N. The test is carried out in three steps: 1) The spindle is driven by a frequency converter under the support of the test bearings to increase the speed from static to 20000 r/min, and the voltage and current values of the frequency converter are recorded every 1000 r/min of speed increase. The product value is the idle power consumption of the electric spindle at the corresponding speed, This power consumption includes electrical power consumption and mechanical power consumption 2) Install two test ceramic ball bearings (FAGHCS7002C. T. P4S. UL) at pre designed positions on the inner spindle of the accompanying bearing. The load situation is the same as above. Record the voltage and current values of the frequency converter every 1000 r/m in increase in speed, and the product value and idle power consumption are subtracted to obtain the friction power consumption of the ceramic ball bearing used in the test at the corresponding speed 3) Remove the test bearing in step 2), install two other test steel ball bearings (NSK7002CTY. P4S. UL) in the same position, repeat the test content in step 2), record the voltage and current values of the frequency converter at this time, and the difference between the product value and the idle power consumption value is the friction power consumption of the test steel ball bearing at the corresponding speed Process the experimental data to obtain a comparison of friction power consumption between ceramic ball bearings and steel ball bearings of the same model, as shown in Figure 2.

Figure 2 Comparison Test Results of Bearing Friction Power Consumption

The experimental results show that ceramic ball bearings have better performance in static friction torque, vibration, temperature rise, and power consumption compared to steel ball bearings of the same model.

4) From Experiment 2.4, it can be seen that the friction power consumption of ceramic ball bearings is smaller than that of steel ball bearings, and the trend is more obvious as the speed increases. Due to the limitation of the electric spindle speed, there is no comparison between the two at higher speeds. However, from existing experimental results, it can be seen that the advantage of low friction power consumption of ceramic ball bearings will be more obvious as the speed increases. This is because the density of ceramic materials is smaller than that of steel, and the quality of ceramic balls is smaller, The centrifugal force is small and the rolling ratio is low, so the ceramic ball bearing has small spin sliding friction, less heat generation, and low friction power consumption. This trend will become more obvious as the speed increases.

1) The static friction torque, temperature rise under high-speed operation, and friction power consumption of ceramic ball bearings are smaller than those of steel ball bearings.

2023 November 4th week XZBRG Product Recommendation:

Full Ceramic Cylindrical Roller Bearings:

Ceramic cylinder roller bearings are made with a single row, two rows, or multi-rows of rolling elements.

the cylindrical roller bearings have line contact between the rollers and raceway, therefore radial load capability is high, making this bearing superior in regards to its ability to withstand heavy loads and impact loads.

They contain cylindrically-shaped roller, which are nevertheless not true cylinders.

Instead, they are crowned or end-relieved to reduce stress concentrations.

This particular geometry results in low friction and allows high-speed applications.