Time : Октябрь 16, 2024

Characteristics of high temperature bearings:

The main feature of high temperature bearings is excellent high temperature resistance, which can run stably in high temperature environment and ensure the continuous operation of equipment. Specifically, high temperature bearings have the following core characteristics:

Excellent high temperature resistance: High temperature bearings can withstand high temperatures from hundreds of degrees Celsius to thousands of degrees Celsius without failure, ensuring the continuous operation of equipment under high temperature conditions.

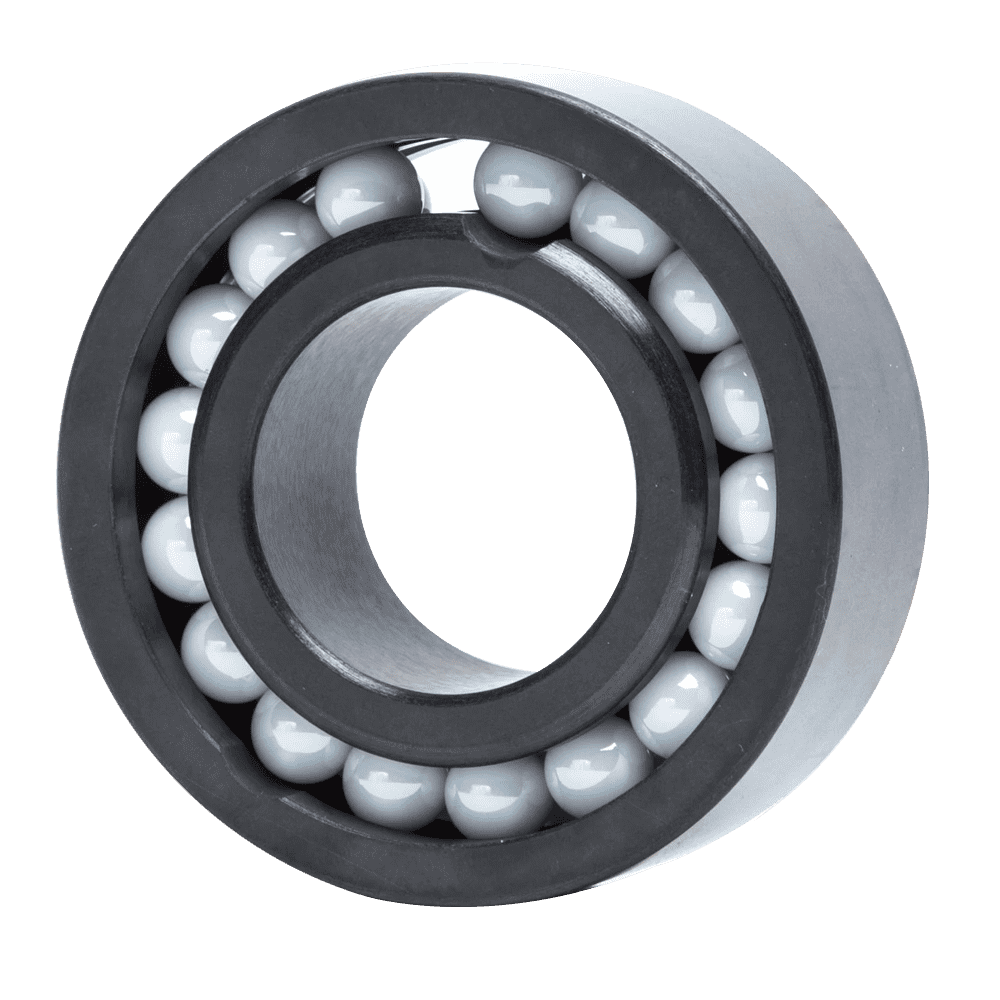

Careful material selection: Usually made of high temperature resistant alloy steel, ceramics or other special materials, these materials are not only resistant to high temperatures, but also have good corrosion resistance and wear resistance.

Structural optimization: By improving the internal structure of the bearing, such as adding heat dissipation channels, optimizing the raceway design, etc., the heat dissipation efficiency is improved and the thermal expansion and thermal stress problems caused by high temperature are reduced.

Lubrication system innovation: Solid lubricants, high temperature greases or specially designed lubrication systems are used to ensure good lubrication effects at high temperatures and reduce friction and wear.

Lifetime lubrication: No grease needs to be added during use, reducing maintenance costs and complexity.

High cost performance: The quality of high temperature bearings is dozens of times higher than that of ordinary bearings, and they have won the trust of customers with their ultra-long service life.

In addition, high temperature bearings also have good sealing properties, which can effectively prevent external pollutants from entering the bearings and reduce bearing wear and failures. These characteristics make high temperature bearings widely used in high-end fields such as aerospace, new energy vehicles, etc.

Selecting the Right Lubrication for Different Temperature Ranges

| Temperature Range | Recommended Lubrication |

| Up to 260°C | Fluorinated grease can be effective. |

| Exceeding 260°C | Layer lattice materials (solid lubricants) are required, but they may not be suitable for clean environments. |

| Above 500°C | Non-lubricated ceramic bearings are often used due to the lack of effective lubricants. |

| Ceramic Bearing | Hybrid Bearing | Steel Bearings(M50, BG42, and XD16N steels) |

Advantages:

|

Преимущества:

Combines the strength and durability of steel rings with the low-friction and high-heat resistance of ceramic balls. |

Преимущества:

|

Applications:

|

Приложения:

|

Приложения:

|

|

|

|